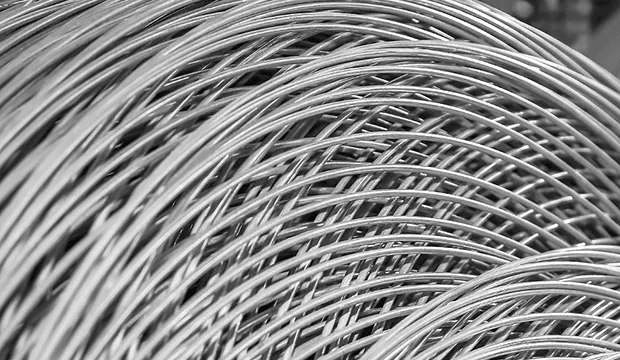

The wire used for manufacturing reinforced razor tape is its structural foundation and determines the operational characteristics of the finished product. It serves as the load-bearing core that absorbs the main mechanical stresses arising during installation and throughout long-term operation of barriers. The quality of the wire directly affects the strength of reinforced razor tape, its elasticity, its ability to retain shape, and its resistance to external influences.

The role of wire in the structure of reinforced razor tape

In the structure of reinforced razor tape, the wire functions as a load-bearing element around which the razor tape made from rolled steel is crimped. This combination of materials makes it possible to unite the cutting properties of stamped tape with the high mechanical strength of a steel core. The wire absorbs tensile and bending loads that occur during the formation of spiral and flat barriers, as well as during attempts at mechanical impact on the fence. During operation, the wire remains under constant stress. It must withstand repeated deformation without failure while maintaining the specified geometry of the structure. For this reason, the requirements for wire used in reinforced razor tape are significantly higher than those for general-purpose wire.

Materials and composition of the wire

High-carbon steel wire is used in the manufacture of reinforced razor tape. The increased carbon content provides the necessary strength and elasticity of the material, which is especially important when forming spirals and other spatial structures. Such wire is capable of retaining its shape after significant mechanical impact and does not lose its properties during prolonged outdoor use. In most cases, galvanized wire is used, which significantly improves the corrosion resistance of the product. The zinc coating protects the steel from moisture, temperature fluctuations, and aggressive environmental factors. This is particularly important for barriers installed in industrial zones, coastal areas, and regions with high humidity.

Mechanical properties and strength requirements

One of the key parameters of the wire is tensile strength. It must be sufficient to ensure that reinforced razor tape does not fail under tension and maintains its integrity even under substantial loads. The elasticity of the wire is also crucial, allowing it to return to its original shape after temporary deformation. Resistance to metal fatigue is no less important. During operation, the wire is subjected to repeated cycles of bending and stretching, especially in spiral barriers. High-quality wire does not develop microcracks and does not break under prolonged exposure to such loads, ensuring the stability of the entire structure.

Uniformity of parameters and quality consistency

For reinforced razor tape, uniform wire diameter along its entire length is critically important. Any deviations may lead to uneven crimping of the razor tape, reduced joint strength, and deterioration of the operational characteristics of the finished product. Consistency of the mechanical properties of the wire ensures predictable behavior of barriers during installation and operation. High-quality wire should not have surface defects such as cracks, delamination, or traces of corrosion. The presence of such defects significantly reduces the service life of reinforced razor tape and may lead to premature failure of the barrier.

Protective coatings and their role

The zinc coating on the wire serves not only an anti-corrosion function but also a protective role during the production of reinforced razor tape. It reduces the risk of damage to the core during the crimping of the razor tape and subsequent installation of barriers. A uniform coating of sufficient thickness makes it possible to ensure a long service life without the need for additional treatment. Under conditions of intensive use, the quality of the coating often becomes the determining factor in the durability of barriers. Wire with poor or uneven coating is more susceptible to corrosion, which negatively affects the strength of the entire structure.

Impact of wire quality on finished barriers

Reinforced razor tape is used to create various types of engineering barriers, including spiral, flat, and combined structures. In all cases, the wire remains the key element that determines the reliability and effectiveness of the perimeter protection system. Strong and elastic wire ensures shape stability of the barriers, prevents their destruction, and complicates attempts to overcome them. The use of high-quality wire makes it possible to significantly extend the service life of reinforced razor tape, reduce maintenance and repair costs, and ensure predictable protective properties throughout the entire period of operation. For this reason, the selection of wire is one of the most important stages in the production of modern engineering barriers.